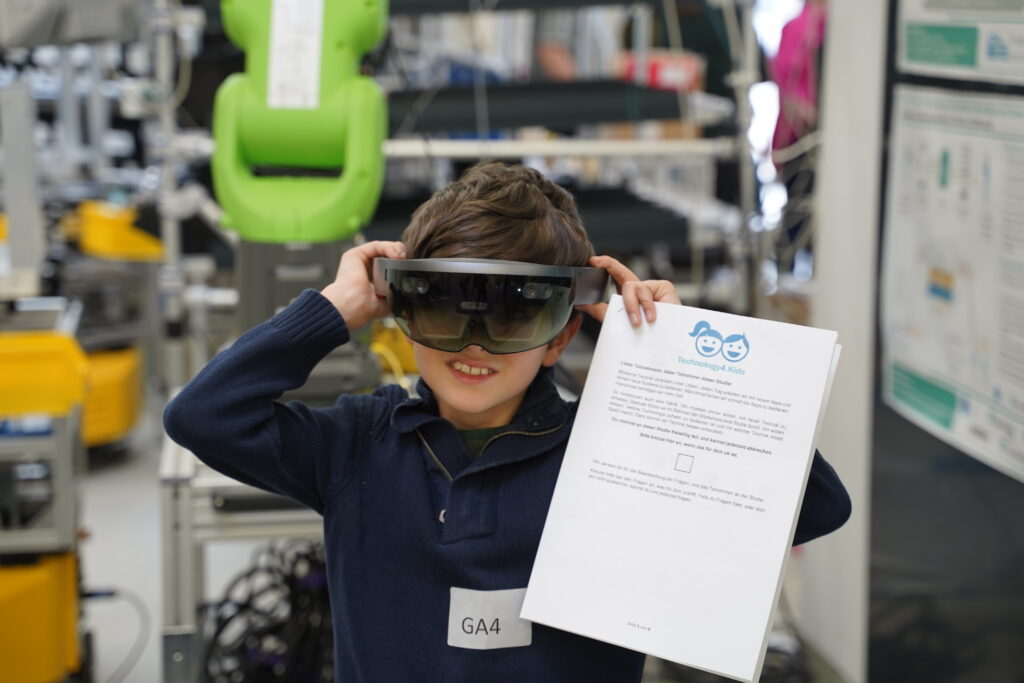

Willkommen in der

Pilotfabrik der TU Wien

Die TU wien

Pilotfabrik

Lern-, Innovations- und Demonstrationsfabrik für Smart Production und Cyber-Physische Produktionssysteme.

Neue Konzepte und Lösungen für die variantenreiche Serienproduktion im Bereich der diskreten Fertigungsindustrie.

Moderne Produktion

für Europa

Flexibilität und Adaptivität sind oft wichtiger als niedrige Lohnkosten.

So wird Industrie 4.0 den europäischen Produktionssektor stärken und zu einer Reindustrialisierung führen.